|

Neyveli,

home of the Neyveli Lignite Corporation, is India’s energy-bridge to the

21st century and a fulfillment of Pandit Nehru’s vision.

Incidentally, Nehru and NLC share a common birthday (14.11.1956). Nehru

launched the mining operations with his golden touch in May 1957. Ever

since, there has been no looking back. NLC has achieved the objectives it

has set for itself, fulfilling its corporate mission to be the leader in the

industry. Comprising of two open cast mines, two Pithead Thermal Power

stations, Briquetting & carbonization plant and a fertilizer plant,

NLC’s growth is sustained and its contribution to India’s social and

economic development is significant.

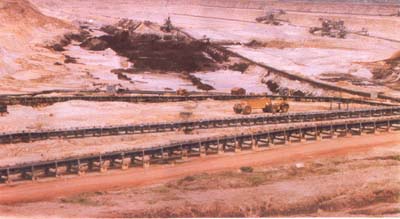

Mine-I

Demarcated over an area of 16.69sq.kms., with a reserve of about 287 million

tonnes, Mine-I is situated on the northern part of the field adjacent to the

Neyveli township. The lignite seam was first exposed in august 1961 and

regular lignite mining was commenced in May 1962. Its production (6.5

million tonnes of lignite per annum) feeds thermal power station-I,

briquetting & carbonization plant and the process steam plant.

While the overburden

thickness varies from 70 to 95m., the lignite thickness is 10 to 23m. German

excavation technology in open cast mining, using bucket wheel excavators,

conveyors and spreaders was used in this mine for the first time in the

country. A huge reservoir of ground water exists below the entire lignite

bed, exerting an upward pressure of 6 to 8 kg/sq.cm., which is tackled by an

effective ground water management system.

TOP

Mine-II

Mine-II is located 5kms

South of mine-I spread over an area of 26sq.kms., with 398 million tonnes

reserve. The lignite seam was first exposed in September 1984 and regular

lignite mining commenced in March 1985. The maximum overburden is 103m and

the lignite thickness varies from 8 to 22m. Initially, the mine was started

with a production capacity of 4.7 million tonnes and in February’83 the

capacity was enhanced to 10.5 million tonnes per annum. The lignite

production in this mine meets the fuel requirement of thermal power

station-II. The method of mining and equipment used are similar to that of

mine-I.

TOP

Thermal

power station-I

An epitome of indo-soviet

collaboration, Neyveli thermal power station-I (TPS-I) was commissioned with

one unit of 50mw in may 1962. Presently, this power station has six units of

50 mw each and three units of 100 mw each.

The unique features of this

power station:

- First

lignite-fired thermal power station in south east Asia.

- First

pit head thermal power station in India

- First

largest thermal power station in south India.

- Continuously

achieving over 70% plant load factor, from 1982-83 to 1991-92 against

the national average of around 50% and has continuously bagged the

meritorious productivity award instituted by the department of power,

government of India.

The power generated from

this thermal power station is fed to the grid of TamilNadu electricity

board, the sole beneficiary.

TOP

Thermal

power station-II

Thermal power station-II (TPS-II)

has been a major source of power to all southern states of India. The 1470

mw capacity power station consists of 7 units of 210 mw each. The first unit

was synchronized in March 1986. The second unit of this power station was

formally commissioned by the then prime minister shri. Rajiv Gandhi. This

power station has seen a series of technological innovations such as:

- Largest

lignite-fired thermal power station in India

- First

and tallest tower type boiler in the country (92.7m. height)

- First

software based burner management system

- First

hydrogen/hydrogen-cooled generator of this size.

- First

boiler to be cleaned by hydrofluoric acid

TOP

Fertilizer

Plant

13.7 Fertilizer Plant with

an installed capacity of 1.52 lakh tonnes of Urea per annum was

commissioned in 1966. The equipment of the Fertilizer Plant were supplied by

M/s. PINTSCH PAMAG,

M/s. Linde of West Germany and M/s. Ansaldo of Italy. Initially the

plant used raw lignite as feedstock. However, due to certain operational and

technological constraints, the

plant was switched over to Low Sulphur Heavy Stock/Furnace

Oil as feedstock since July 1979.

TOP

Briquettting

and Carbonization Plant

13.8 Briquetting and Carbonization

Plant was commissioned in 1966 with an installed capacity

of 3.27 LT of Carbonized briquettes (Leco) per annum. The equipment were

supplied by consortium of West

German firms. The achievable capacity has been subsequently

assessed as 2,62,000 Tonne of Coke per annum. Coke is used in Electro

chemical, Electro

metallurgical industries as a reductant and in tea sector as a versatile

fuel for drying and also as

substitute for coal, in cement and paper industries. In the process

of low temperature carbonization adopted in the plant base chemicals vital

to the chemical

industries viz. Carbolic acid, Orthocresol, Metaparacresol, Xylenol,

Multivalent phenol and

neutral oil are also produced.

The plant is under temporary suspension since 5th April 2001 owing to

inadequate market

demand. The plant is about to be relinquished by NLC.

TOP

|